Category: Acceletronics

Join us at the 61st AAPM Annual Meeting

Join us at the 61st AAPM Annual Meeting

July 14-17,2019

Henry B. Gonzalez Convention Center

Radparts.com, along with our sister company, Acceletronics, is exhibiting

at the 61st Annual Meeting of the American Association of Physicists in Medicine in San Antonio, TX.

Stop by the booth and check out the new TheraView Total Body Imager

Proper Maintenance Keeps Medical Systems Running Smoothly

The manufacturer of all medical equipment routinely establishes a regular maintenance schedule that customers need to be able to accomplish in order to ensure that their system is running properly. These maintenance requirements ensure tests are run to ensure that certain linear accelerator parts are all functioning well. The same is true for oncology equipment parts.

Importance of doing regular proper maintenance

When the equipment you are operating is designed for diagnosing a wide range of serious injuries, illnesses, and diseases it is extremely important that they are working optimally at all times. To be sure that all of your machines are properly maintained you should read all of the documentation that comes with each machine and pays close attention to any section that lists regular or scheduled maintenance.

8 Steps Involved in Quality Preventative Maintenance Plans on Medical Equipment

#1 Get the key people in your organization on board with the plan

– In order for any maintenance plan to work you need to be sure that you have all of your people on board with your plan.

#2 Discuss your goals for the plan –

Be sure to discuss all of your goals for the program with everyone to be sure everyone understands them.

#3 Do an initial inventory of all the equipment needing to be maintained –

You should a complete inventory of all of the equipment that will be part of your plan.

#4 Make decisions on the plan you wanting to follow –

Make final decisions on how the plan will be carried out.

#5 Read through all of the equipment manuals –

It is important to know as much about the machinery as you possibly can before you get started.

#6 Schedule long-term maintenance plan –

Set up a long-term maintenance plan that covers all of the vital systems of the equipment.

#7 Schedule short-term maintenance plan –

Set up a short-term plan that covers a more basic look over of the system.

#8 Train your people –

Before you set your plans in motion you want to be sure that all of your people are all on the same page and ready to carry out the mission.

For some medical facilities this type of maintenance on each piece of equipment requires a special department within the organization. For others it is more cost effective to outsource medical equipment maintenance and repairs to a company that specializes in the repair of medical equipment and parts needed for complex repairs on large scaled equipment such as linear accelerators, CT scanners, and a variety of radiation oncology equipment.

Learn more about Radparts and the variety of services and parts they offer to repair medical equipment including: linear accelerators parts, CT scanners parts, linac parts, and radiation oncology equipment at www.radparts.com. To contact one of our medical equipment repair specialists for parts or service call toll free 877.704.3838 for 24/7/365 support.

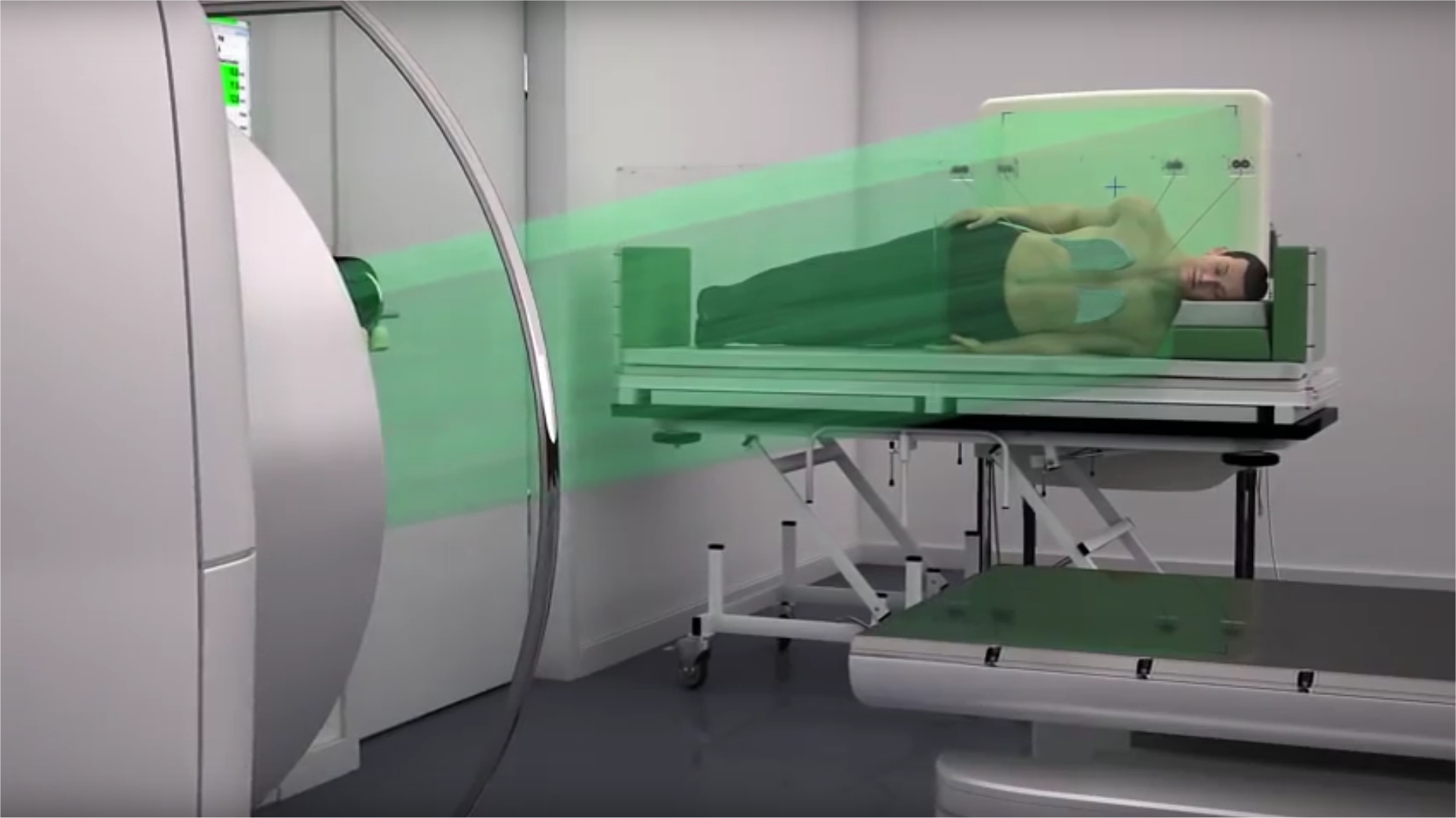

Theraview TBI (Total Body Irradiation) Image Guided RadioTherapy System

Bring new confidence, reliability and safety on-line with TheraView®, the cost effective, low-dose, high resolution IGRT digital portal imaging and workstation software solution.

Acceletronics is North America’s full service and sales dealer for Cablon Medical’s latest TheraView Technology IGRT solutions.

The TheraView TargetCheck® IGRT workstation, which connects to your existing OEM portal imaging system, is delivered web-enabled to allow remote access for review and has image management network options available that bring the full functionality of TargetCheck®, TheraView’s powerful beam alignment verification software, to remote workstations thru-out the department.

options available that bring the full functionality of TargetCheck®, TheraView’s powerful beam alignment verification software, to remote workstations thru-out the department.

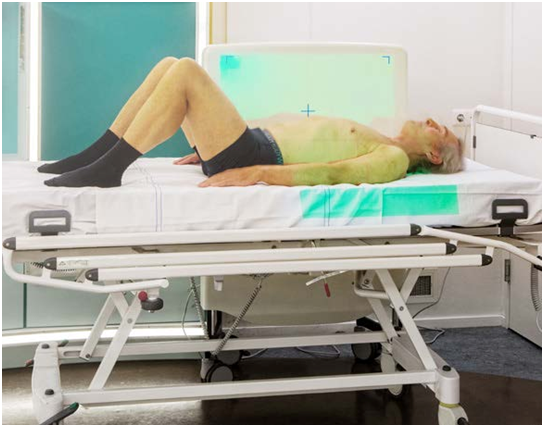

The TheraView TBI (Total Body Irradiation) Image Guided RadioTherapy System can help you significantly improve TBI treatment procedures and outcomes. This flexible, mobile stand-alone imager is part of the integrated TheraView imaging product suite and the only commercially available TBI product of its kind today. Faster results, fewer errors. Instead of simply producing a single image, our solution relies on Intrafraction Monitoring in the form of live video capture to provide high quality megavoltage (MV) images. Video captures can be stopped and restarted to accomodate for changes in the patient’s position – so there’s no risk of needing to repeat the entire patient setup procedure. This will deliver significantly greater efficiency, faster results and improved treatment quality.

The TheraView Couch Setup Assist (TCSA), is an optional hardware/software solution that enables a faster, more accurate positioning of your patient. With TCSA, you can enhance patient care by reducing time spent on the treatment table and the number of trips in and out of the room by the Therapist. TCSA helps position the patient quickly with precision, reducing setup misalignments during patient setup. TCSA integrates with most all treatment couches and all movements are retraceable from the main application.

For the department that needs an EPID installed on their existing Linac, the TheraView EPID for IGRT uses high reliability, less costly, radiation hardened, cooled C3D digital X-Ray camera technology for excellent, reliable and stable image quality, with a fiber-optic digital image transmission path to the workstation providing a virtually noise free image. TheraView mounts on any non-beam-stopper linear accelerator and provides superb real-time portal imaging. TheraView is DICOM-RT compatible with all popular image management systems and has motorized digitally controlled movements for accurate and easy set-up, use and stowage.

superb real-time portal imaging. TheraView is DICOM-RT compatible with all popular image management systems and has motorized digitally controlled movements for accurate and easy set-up, use and stowage.

Continual development by the experts at TheraView consistently deliver advanced timely solutions with changing treatment protocols. With the Theraview TargetCheck® IGRT workstation, TBI Image Guided RadioTherapy System or Theraview EPID, manufactured by Cablon Medical (www.theraview.com) you can deliver the current and future technology treatments with accuracy, verification and safety. Please contact us to discuss your MV imaging needs and schedule an online demonstration, we can be reached via email at info@acceletronics.com or call us at 800-543-5144.

More information can be found on our website: http://www.acceletronics.com/medical/theraview-igrt-portal-imaging-system.php

and on YouTube Video: https://www.youtube.com/watch?v=R9_UAk8DMt4

Custom Liquid Cooling Systems from Laird Optimize Particle Accelerators Performance

Laird has developed self-contained liquid cooling systems (LCS) that deliver optimal temperature stabilization for more precise temperature control in particle accelerators like linear accelerators (LINACs) and cyclotron systems. LINACs and cyclotrons increase the kinetic energy of particles for use in a variety of applications, ranging from scientific studies on particle physics to radiation therapy for cancer patients. Temperature control within the linear accelerator and cyclotron systems is critical for operational integrity, performance accuracy and system reliability.

One example of a LINAC system is Intensity-Modulated Radiation Therapy (IMRT) equipment used for treating cancer. IMRT equipment requires thermal consistency to maintain beam energy and stability. The tungsten target, the waveguide, the acceleration chamber, and the magnets all require thermal management to dissipate heat buildup and maintain temperature stability for optimal operation. Even the cabinet electronics, amplifiers and power supplies, require cooling due to the heat generated during operation. For example, certain components in an IMRT system, such as the process board, require thermal control within about 0.5 degree C.

Cyclotron systems, like Positron Emission Tomography (PET) scanners, require cooling of both the cyclotron equipment that generates the radioactive substance and the detector banks in the imaging system. The amplifiers, power supplies, and vacuum chamber also need cooling. To avoid noise in the image due to leakage current, the detectors need to be kept at a constant temperature relative to one another.

Liquid cooling systems recirculate coolant to a predefined set-point temperature, while dissipating the large amount of heat generated in the densely packed electronic environment of IMRT and PET systems. An LCS offers higher efficiency than air-based heat exchangers and provides more rapid cooling, quieter operation, higher reliability, and increased system uptime.

Laird offers three types of liquid cooling systems to meet most any application demands: liquid-to-air configuration; liquid-to-liquid configuration; and compressor-based chiller system. Depending on system requirements, additional features for precise temperature control and variable coolant flow rate, coolants with corrosion inhibitors, and coolant filtration are available. In IMRT and PET systems, temperature control of multiple liquid circuits is often required, as is high operational temperature. Control of multiple pressure, flow, and temperature settings can easily be accommodated in a single system design.

Given the complexity of some IMRT and PET systems, usage of a custom designed LCS with plug-and-play components may be a good solution. For example, quick connect fittings allow easy service and maintenance, such as a bottom drain for removing the coolant by gravity, or a pump that is easy to swap out to simplify ease-of-service. Custom housing configurations for unique environments may also be required. Laird has the knowledge to custom design liquid cooling systems for linear accelerator and cyclotron applications, as well as the experience to support and service them.

“The increasing intricacy of thermal management means that linear accelerator and cyclotron systems often require custom liquid cooling systems. Laird’s experience in the design, manufacturing, and servicing of liquid cooling systems, as well as our expertise in pumps, compressor technology, heat exchangers, and electro-mechanical controls allows IMRT and PET manufacturers to focus on their end product design, while leaving the thermal management issues to the experts,” said Anders Kottenauer, Senior Vice President of Laird’s Engineered Thermal Systems Business.

Laird

Original Source: http://www.designworldonline.com/custom-liquid-cooling-systems-laird-optimize-particle-accelerators-performance/

Original Author: Taylor Meade

Original Date: June 1, 2017

TheraView TBI gets 510k approval

TheraView and its Distributor Acceletronics are proud to present the first commercially available mobile Total Body Irradiation (TBI) detector. With its unique software features, radiation therapists can easily follow the entire TBI treatment. An easy setup on any Linac makes the patient treatment very efficient and accurate. During a live video stream the system will warn the user of any patient deviation by a change in color scheme or clinical audio alarm.

Please take a moment to visit our website TheraView page which has a link to the new TBI Imaging system brochure.

We are available for an onsite or online demo at a convenient time to share this new product with you and your team.

Contact us at info@Acceletronics.com or call 800-543-5144.

Toll Free 1-800-626-8704

www.acceletronics.com

Different Applications of Linear Accelerators within the Medical Industry

Many of us have never heard of a linear accelerator. Unless you are in the medical field or involved in radiation treatment you might not realize how important this one piece of medical equipment is to the health care industry. No time is a good time for medical facilities to have a piece of equipment down but especially so in the case of radiation oncology equipment like linear accelerators.

This is one of the main reasons that replacement parts for linear accelerators and other radiation oncology equipment are in high demand. When a piece of radiation equipment breaks down it is crucial to the treatment of patients that it is repaired quickly to avoid downtime in patient care. In this installment we will look at the applications of linear accelerators in medical facilities.

- Radiation Treatment For Cancerous Tumors

Linear accelerators are mainly known as the machine that is used in radiation therapy to target cancerous tumors. Linear accelerators accelerate electrons. When they are speeding up, that is when they would be getting the heavy metal target. This is where the x-ray would be generated. Once that radiation is generated, then only it is targeted towards the tumor. This is one of the first methods used in chemotherapy that targets and destroys cancerous tumors. Without the actual acceleration of the electrons, the radiation which is required for the radiation therapy would not be produced at all. That is why the linear acceleration is always required when it comes to the radiation therapy.

- LINAC Treatment

This treatment is similar to the laser technique which is used in a wide variety of cosmetic treatments. This ensures that the healthy cells and issues around the area where it is focused are not destroyed as well. This is the reason that this application is used in treatment. The risk of destroying the healthy tissue is minimized because the radiation is focused in on the tumor.

- MRI

Linear accelerators are also used in MRI tests. In this test, the scanning of the different body parts is conducted in order to find out whether there is any problem with these body parts. The electrons are accelerated in order to produce the right kind of effect.

These are just some of the applications linear accelerators can be used within the medical industry. We can appreciate why there is such high demand for replacement parts for linear accelerators and other types of radiotherapy equipment knowing how crucial on time treatment and regime is in treatment.

Learn more about Radparts and the variety of services and parts they offer to repair medical equipment including: linear accelerators parts, CT scanners parts, linac parts, and radiation oncology equipment at www.radparts.com. To contact one of our medical equipment repair specialists for parts or service call toll free 877.704.3838 for 24/7/365 support.

What Is a Linear Accelerator?

A linear accelerator is a device that uses high Radio-Frequency (RF) electromagnetic waves to accelerate charged particles to high energies in a linear path, inside a tube like structure called the accelerator waveguide. The resonating frequency of the medical linac is about 3 billion Hertz cycles per second. This is the most common device to treat cancer with external beam radiation. Accelerator is basically an apparatus for accelerating charged subatomic particles, used in radiotherapy, and the production of radionuclides.

A pulsed electron beam generated by an electron gun passes through a long, straight vacuum tube containing alternating hollow electrodes. The electrodes are arranged so that, when their high frequency potentials are properly varied, the electrons passing through the tube receive successive increments of energy. The electrons are stopped abruptly by a heavy metal target and directed by a collimator to deliver super voltage X-Rays to the patient receiving radiotherapy.

The linear accelerator (Linac), uses microwave technology to accelerate electrons in a part of the linac called waveguide, then allows these electrons to collide with a heavy metal target. As a result of these collisions, high energy X-Rays (Photons) are produced from the target.

Linear Accelerator Technicians: Performs advanced technical support related to the maintenance and operation of medical linear accelerators. Jobs include preventive maintenance scheduling and responding to down linear accelerator parts and services, Coordinates vendor service and documentation, when necessary. Maintains inventory and orders parts for linear accelerators. Can assist in the design and modification of treatment accessories for physics and other departmental equipment as needed for patient treatment, quality assurance and research support. May require an ASEE or equivalent or Bachelors’ degree in Electrical or Mechanical Engineering or a directly related field. A senior position requires five (5) years of directly related experience maintaining and servicing medical linear accelerators. Specific experience is typically required on Varian Linear Accelerators. Authorized Varian training is highly desirable. Manufactures of these items include Siemens, Philips, Varian, and Elekta. Repair organizations include Acceletronics, Centura, and Altair.

When linear accelerator parts and services breaks down it is imperative that repair services are almost immediate. Downtime in a medical setting can literally be the difference between life and death so having the ability to have direct access to medical equipment repair services should be of the outmost priority. Another detail that is forgotten is the urgency of finding the parts for medical equipment. Without the proper parts to fix down machines technicians are at a stalemate with getting much need equipment like LINACS and CT scanners up and going again.

Having instantaneous access to OEM replacement parts for Linear Accelerators, Radiotherapy CT Simulators and Radiation Oncology equipment is pertinent. With newer equipment it is often difficult to find access to replacement parts. Newer medical equipment can be difficult to find replacement parts for simply because of the newness of the piece to the market.

Radparts is the world’s largest independent distributor of OEM replacement parts for Linear Accelerators and Radiation Oncology equipment. We provide high quality, user friendly, low cost parts support for linear accelerators and radiation equipment. For more information on low cost parts for repairing Linac equipment find us at http://www.radparts.c

Choosing refurbished vs. new

The best cancer treatment starts when patients have a proper diagnosis. It is crucial to have a definitive plan of action when treating cancerous tumors. Top medical facilities, skilled professionals, proper medical equipment, and a complete and accurate diagnosis allow patients to have the best possible outcome with their cancer treatment.

Radiation therapy is used in the treatment of most cancer patients. This is true even when patients are being given a cocktail of other drugs used to treat cancer. Radiation is a service that is provided by oncology practitioners. According to a research, about 60% or more cases involving patients with cancer in the United States undergo radiation therapy to treat or cure their cancer. Radiation cannot be delivered with using a linear accelerator.

A linear accelerator is machine that is able to shoot radiation onto the cancerous tumor without damaging the surrounding healthy tissue. With innovative attempts to make linear accelerators more advanced, they would give guaranteed accuracy at all times. This will ensure the least possible impact on the surrounding tissue around the tumor. Damage to the surrounding tissue is one of the greatest drawbacks of using radiation in the first place. This issue can come to an end with this more technological attempt at radiation treatment using linear accelerators in treatment.

Oncology care providers can only get the equipment their facilities can afford to purchase. New linear accelerators can cost upwards of four million dollars. This is where purchasing a refurbished linear accelerator can sometimes offer facilities a chance to offer top notch treatments at a fraction of the cost. Refurbished medical equipment can save companies upwards of fifty percent off the cost of buying new.

Refurbished equipment is reliable, secure, and effective while taking in consideration your facilities budget and is surely a good approach to offer to cancer patients. These newly advanced linear accelerators offer precise treatments that are carried out by best of engineers and technicians.

One of the most important reasons to buy a refurbished accelerator is that it frees up your remaining budget to help you continue to grow your practice. With updated equipment you have the chance of treating more patients. This in turn increases your experience and your practice. With a refurbished linear accelerator you have more chances of saving the patients you treat and curing them of cancer. Advances in technology and equipment give your patient’s confidence in the effectiveness of your treatments.

Radparts is the world’s largest independent distributor of OEM replacement parts for Linear Accelerators and Radiation Oncology equipment. We provide high quality, user friendly, low cost parts support for linear accelerators and radiation equipment. For more information on low cost parts for repairing Linac equipment find us at http://www.radparts.com.

Outsourcing Medical Equipment Maintenance

Medical facilities need to depend on outside medical equipment service providers when in-house service specialists are not on staff. Regular maintenance, including preventative and corrective measures, needs to be done to keep medical equipment safe and running smoothly. Updating software and worn parts adds to the longevity of medical equipment thus resulting in savings for your facility.

Many facilities try to cut corners by having personnel perform regular maintenance and minor repairs. While this may occasionally work it is always better to enter into a service contract with a third party service company or equipment vendor to perform corrective and preventative maintenance. A service contract will ensure that your equipment is maintained at regular intervals. This will help to combat against unexpected machine failures. There are several options when choosing a service contract. We will look into the options below.

Third Party Equipment Service Contracts Available To Medical Facilities

- 24/7 Full Coverage: A medical facility can request services anytime, day or night.

- Business Hour Coverage: With this type of service contract a medical center will receive service during normal business hours, five days a week for eight hours a day.

- Extended Business Hour Coverage: This service contract offers the same coverage as business hour coverage except that it covers more than eight hours. If your facility is open from nine in the morning until nine at night this would be one of the contract options to consider.

- Extended Business Hour and Weekend Coverage: Similar to the above except it adds hours to cover facilities on the weekend.

- Preventative Maintenance Coverage: This type of service contract only covers planned maintenance and does not cover unplanned corrective services.

- Time and Material Coverage: A time and material coverage contract is where a service provider is paid based on the actual cost of parts and labor used. This contract is usually based on a specific cost per hour of labor.

- Loaner Service Contract Coverage: This type of contract allows medical facilities to return the unit to the vendor and the vendor provides a loaner unit until the equipment is returned to its original state. This is a difficult service contract to have in place with large scaled equipment such as linear accelerators and ct scanners.

In our next installment on medical equipment service contracts we will discuss tips on negotiating a contract that best meets your facilities needs while maintaining a reasonable budget.