Often, when a patient is older in their years and receives the bad news that they have fallen victim to a form of cancer, they begin to come to terms with the fact that their lives will soon be over due to it. This sense of thinking does not have to be a person’s future outcome since with today’s technology no matter a person’s age, cancer treatment is a very promising option to be used. However, studies have shown patients aged 90 years or older are not even being offered any treatment at all. In this article the statistics of elderly patients and their success rates of using radiotherapy as a treatment option are shown and how even at an older age these patients have gained significant years added to their lives, which can be very worthwhile. With new techniques and technology, the treatment can be much less invasive without needing surgery and can truly be a lifesaver for many of lives young and old.

Should You Buy a Used Linac Over a New System?

Medical-grade Linear accelerators are investments, not an impulse buy. That being said, a linear accelerator is an essential tool in any oncologist office. Owners of a medical oncologist clinic have the option of purchasing a new linac system or invest in a used system, and there are advantages and disadvantages for both. You can essentially break the parameters into three (or more) situations:

Your Office Space

The space and size of your medical office or clinic is a good factor when deciding to go either used or new for a linac system. Smaller clinics will benefit from a used system, especially those with a small client-base that don’t move through more than a handful of patients a day. This also pertains to offices that are new and just getting started, or established offices that are small in space. Offices and clinics just starting up can go with a used system at first and upgrade to a brand-new system when the profits call for it.

Your Intentions

Not all offices and clinics revolve heavily around the use of a linac, but rather use it sparingly. This is a simple reason to go with a used system over a new one. Operating these systems can get expensive, and offices that heavily use a linac system with all the bells and whistles accompanying it have better use for a shiny new device. Conversely, those offices or clinics that only use it sparingly can go with a used model that is more stripped down to a model precisely tuned for their needs. You also may be a new office with the intention of having a higher-level model in the future, but current-day budgets don’t allow it, which calls for a more budget-friendly used system.

Your Experience

Is your office or clinic moving? Do you have any intention of moving in the next year or so? Are you generally a busier clinic with many patients? New linac systems are great for busier and more modern clinics but for those with the need for backup units a used system is better to keep on hand for when a new system breaks down, especially with all the parts that go into such a device. Similarly, if you’re a clinic that has plans to move everything it may be easier for the future if you go with a used system that will be installed only to be uninstalled for a big move. Even higher-tiered clinics can find themselves moving, so this is something to keep in mind when setting up a clinic initially when starting up.

Medical grade linear accelerators are a product in which all oncologist clinics should be investing. That being said, making a purchase can be smarter when going with a used system rather than new; it just depends on your office space, intentions with the system, and overall experience of running your clinic.

Radparts is the world’s largest independent distributor of OEM replacement parts for Linear Accelerators and Radiation Oncology equipment. Radparts provides high quality, user friendly, low cost parts and support for linear accelerators and radiation equipment. More information can be found at https://www.radparts.com/.

Inventory Insider

November Monthly Specials

Happy Halloween!

Knowing the Ins and Outs of Linac Repairs Part 1

Understanding the complexities of linear accelerators can be rather difficult since these machines are such large, expensive machines. A linear accelerator operates by delivering external beam radiation treatments to patients fighting cancer, but they also include additional imaging systems that are attached such as portal dosimetry or onboard imaging which too add to the complexity. Due to such precise functionality of such a variety of parts inside the unit, it is crucial for any clinic to have the proper expertise on-site to work on these machines and know exactly what these systems do.

The Importance Of Treatments

Investing in proper expertise is a very serious matter for the oncology department to consider due to the fact that patients receiving the treatment must continue a regular schedule with as little amount of downtime as possible because of the cumulative effect that radiation has on the cancer cells and if treatment is stopped, the entire treatment process will have to be restarted all over again.

In-Depth Training

A clinical engineer not only needs to know how to complete a repair on a broken or damaged part of a linear accelerator but needs to understand the actual process of how the equipment is designed to work during treatments. Troubleshooting can be very difficult if not familiar with the problem that is being described by the clinic operators. It is part of the technician’s job to be able to translate what an issue could be related to a piece of software or hardware component. Developing this skill set and the understanding of linear accelerators takes a great deal of time and not always be taught in just a few sessions of training during a treatment occurring. Training alone is not effective enough when needing technicians to perform repairs at clinics. Vendor service schools can range anywhere from $20,000 to $30,000 or even possibly higher depend on the level of expertise. The portion for training on linac is roughly 6 weeks of school during a 2-year period however additional schooling can be done for onboard imaging as well. The entire process could take 3 to 4 years to complete which will include hands-on experience.

Finding The Right Time for Repairs

Linac parts are regularly checked during preventative maintenance visits which are generally recommended by the manufacturer to occur 3 to 4 times each year. Each maintenance visit requires detailed checklists and the individualized machines also have onboard alert systems programmed to shut off a device if a problem is found to prevent safety concerns. The most difficult question that needs to be solved is when can time be taken to actual repair the Linac equipment? In many facilities, patients are scheduled every 15 minutes throughout an 8-hour period, 5 days a week. With the importance of continuing treatments for a clinic’s patients, downtime is the worst part of the day. If possible, a technician will bypass the issue and continue limping along, treating patients when possible. Much service work is then performed after hours or on nights/ weekends. Some clinics choose to have a backup machine when these instances occur and one needs repair but this adds on additional costs and still extended hours added to a facility.

Radparts is the world’s largest independent distributor of OEM replacement parts for Linear Accelerators and Radiation Oncology equipment. Radparts provides high quality, user friendly, low cost parts and support for linear accelerators and radiation equipment. More information can be found at https://www.radparts.com/.

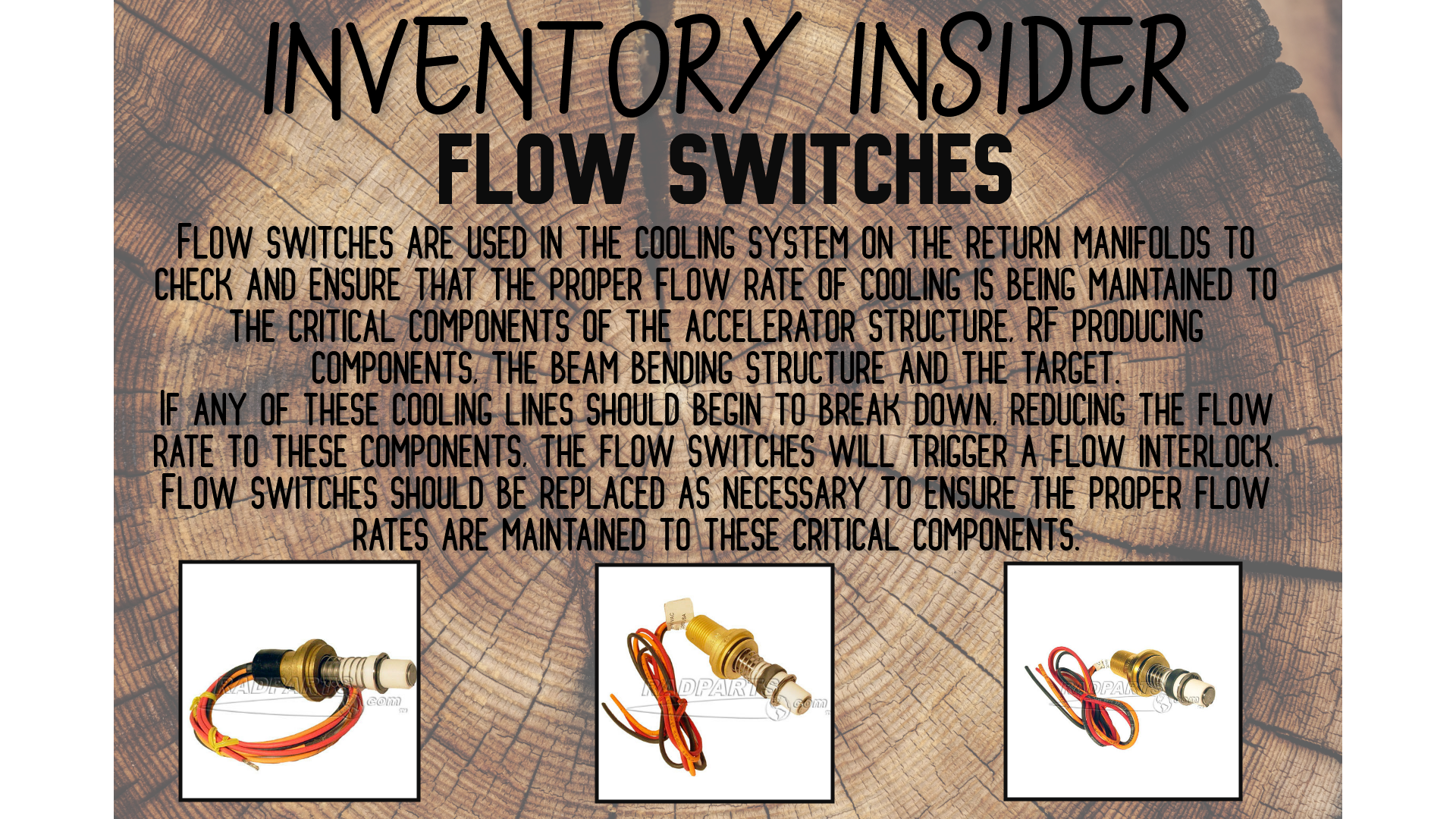

Inventory Insider Flow Switches

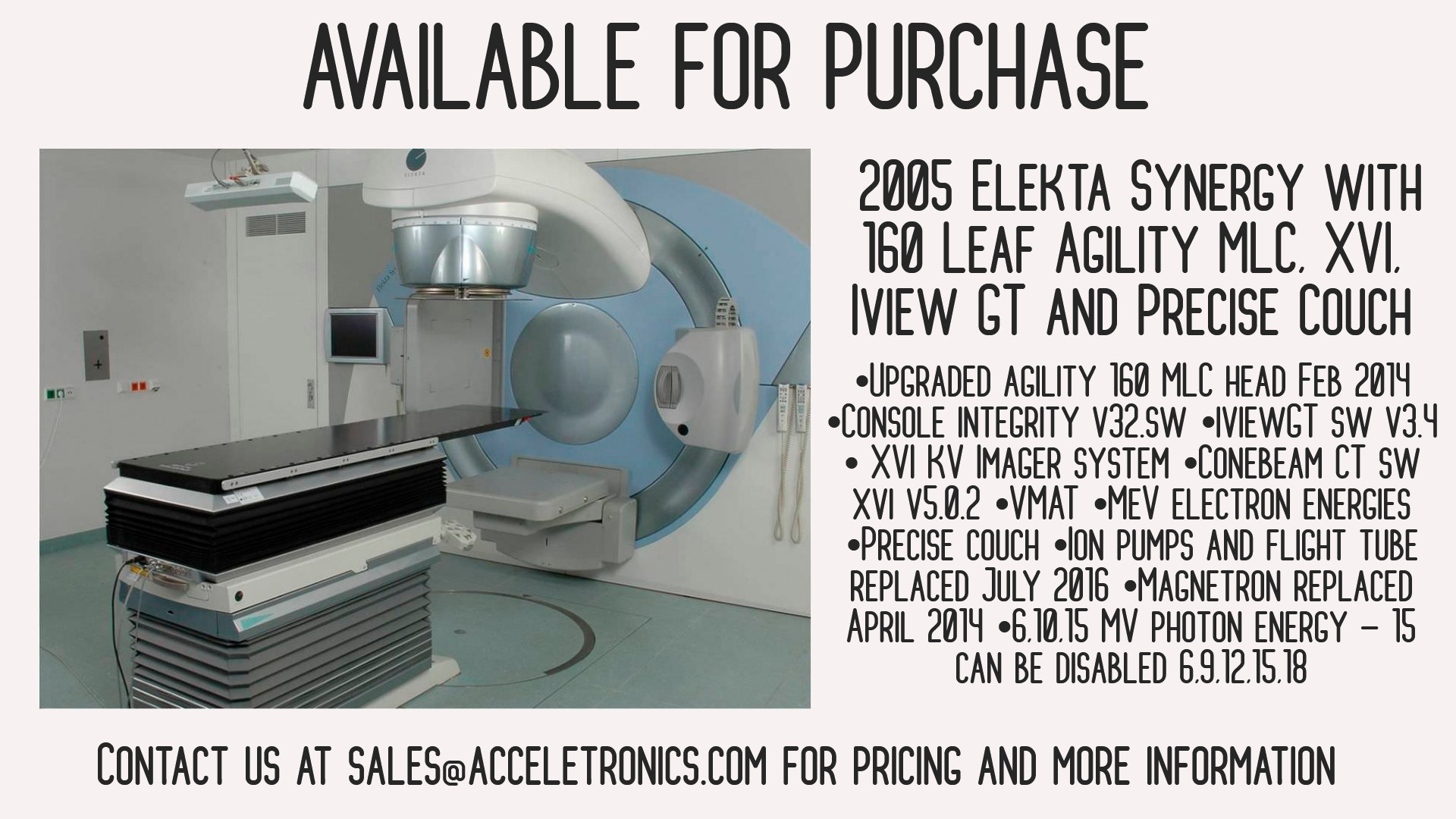

2005 Elekta Synergy Available for purchase

Missed us at ASTRO?

Using High Energy Electrons To Fight Cancer

Researchers as CERN are always working to find new options for radiation therapy to be more effective and more affordable. Radiation therapy is a procedure that utilizes special equipment called a linear accelerator that emits a beam of electrons into a targeted area of a cancerous tumor on a patient. At high concentration, these x-ray beams can produce a larger enough dose of radiation to kill the cancer cells. Unfortunately, even with very precise placement, the x-ray can cause damage surrounding healthy tissue and organs, so doctors have many obstacles to overcome with effective cancer options still. New developments at CERN are showing great possibilities for the future by creating a electron accelerator called CLIC which uses high energy electrons in a smaller setting and more affordable. In this following article, it describes more in detail the process of this new found technology and how its can further change and evolve radiation treatment from where it is today.